6 Problems You Can Solve With QME Tool Management Software

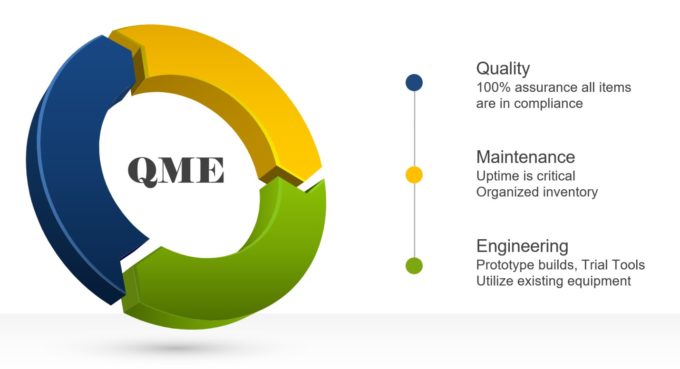

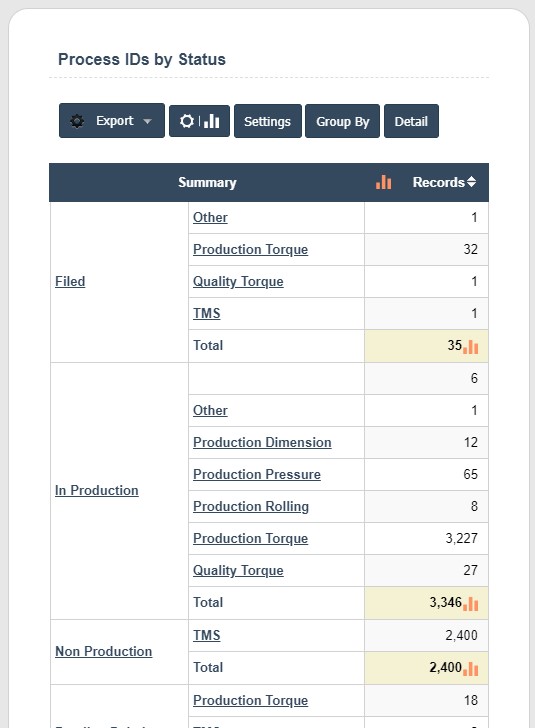

Encore System’s proprietary QME (quality/maintenance/engineering) tool management software was exclusively developed by software and computer engineers who understand the importance of a plant manager’s ability to access master data. Within the realm of tool management, master data can include PM (preventive maintenance) dates, calibration records, inventory status, root cause failure analysis data, and much more.

Our QME software is specifically designed to help manufacturers improve service and product quality, ensure on-time completion of preventative maintenance, and prevent these six common problems.

Problem #1: Unplanned Downtime

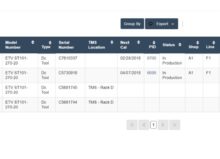

Not knowing when certain tools are scheduled for maintenance service or calibration often results in unplanned downtime. Our QME software makes it fast and easy to track the status and last servicing/calibration date of all tools and their components in your inventory. Additionally, our software’s accurate inventory tracking helps you know exactly if and when you need to buy more of a certain component or tool to prevent downtime.

Problem #2: Unprepared for an Audit

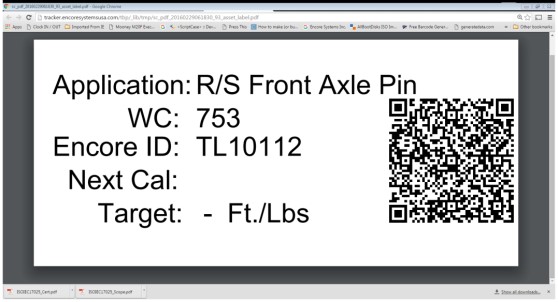

All ISO-accredited facilities are mandated to keep their tools calibrated because they ensure the integrity and soundness of the products made and assembled. Calibration certificates usually include the name of the product/device, its identification number, the parameters calibrated, and the date of the last calibration among other data.

QME software keeps calibration data immediately accessible so you know when tools need or have been calibrated. In addition, this software tracks all aspects of the production process, repair information, test results, and type of preventative maintenance work performed on the tool. It is essential to have this information ready to show to ISO auditors. Failing to provide data required from an ISO audit could result in your accreditation being suspended.

Problem #3: Unexpected Repairs

Precision, state-of-the-art assembly tools demand regular maintenance or they risk failing unexpectedly during production or causing safety issues for end-users. Losing track of when a tool is due for calibration and inspection will ultimately lead to that tool breaking down, stopping production, and accruing unnecessary downtime costs. With QME tool management software tracking the status and repair/maintenance history of each tool, the risk of expensive repairs and downtime is virtually eliminated.

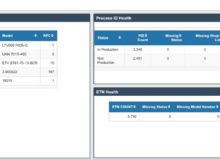

Problem #4: Over or Understocking Parts

QME tool management software can also prevent common inventory issues like overstocking and understocking. Overstocking parts is not only a waste of money, but also takes up space in a warehouse. Overstocking can also be an issue if the part eventually becomes obsolete. Alternatively, understocking is a huge problem affecting plant managers who lose track of available part quantities.

In addition to overstocking and understanding, large warehouses that don’t use tool management software also risk losing parts or ordering parts that they already have in stock.

Problem #5: Losing or Misplacing Parts

Because QME software seamlessly monitors and manages tools, you will always know precisely where every tool or part is located throughout your plant. Instead of spending valuable time searching for tools needed to support a production project, QME gives you the information you need to immediately find that tool.

Problem #6: Prototyping Errors

Lastly, you can use our QME software to prevent errors during the prototyping or remanufacturing processes. As a tool management system, QME allows you to input all types of technical data about a specific product. That way, if one of your tools suddenly fails and you need to remanufacture or retrofit it, your engineers have all of the information they need to start either process.

Learn More About Encore’s QME Software Today

Encore Systems is an industry-leading provider of DC tool repair services, ISO-accredited torque calibrations, and tool management services. Contact us today to learn more about our QME software or to schedule a free evaluation of your tooling needs.