5 Reasons Why You Need a Tool Data Management System

Tool data management is a way to effectively manage your workplace’s inventory. If you haven’t implemented tool management software yet, you may be missing out on an incredibly important resource. In this article, we’ll cover the overall benefits of tool management software and how you can implement it in your workplace.

Let’s get started with an overview of what tool management software is.

What Is Tool Management Software?

Tool data management software supports the overall upkeep and performance of your equipment and tools. Without it, you risk losing important information.

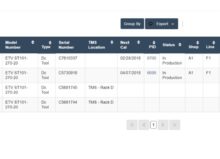

With this type of software, you can log all equipment, machinery, and parts that you have in your workplace. You can also record information about each part/equipment, including calibration data, dates/times/costs of past repairs, preventative maintenance (PM) reminders, and so much more.

Encore Systems has our own custom QME (quality/maintenance/engineering) tool tracking software. This software is web-based and designed for plants/facilities that need to stay ISO-compliant. Visit our website to learn more about our proprietary software, or keep reading to learn more about the top five benefits of using tool management software.

Benefits of Tool Management Software

As previously mentioned, the main purpose of tool tracking software is to help businesses better manage their inventory. Having this type of information on hand at all times will help your business in so many ways…which brings us to our next section: the top five benefits of tool tracking software.

1. Maintain Quality & ISO Compliance

Whether you’re getting your ISO certification or undergoing your yearly surveillance audit, having a tool data management system is essential. Tool tracking software will help you capture key information about each part or component that you have. Plus, when you implement software that’s specifically designed for ISO compliance, you’ll have all of the information that you need to stay prepared now and in the future (e.g. record of design changes, product characteristics, etc.).

2. Ensure Better Decision-Making

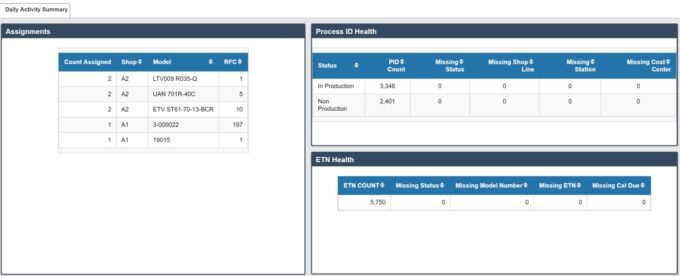

As a business owner, you know that your key performance indicators (KPIs) are important. After all, they help you measure your success. If you’re looking for data-driven solutions that will help you better identify your KPIs, you should consider investing in a tool management system.

This type of system will allow you to record the total number and cost of repairs for the year, the total amount of tools that have been repaired during the year, tool statuses, and more. Having a record of this type of information will help you make better decisions.

3. Improved Data Sharing & Expansion

Whether you need a list of your available spare parts or a record of your recently calibrated equipment, you can achieve all of that and more with tool management software. This type of software will allow you to generate your own custom reports that are both easy to read and manage.

4. Save Money

Are you spending more than you should? Tool management software allows you to take a closer look at your inventory, how much you’re typically spending on repairs, and how efficient your current production cycle is. Identifying any weak spots will help you not only save money, but also increase uptime.

5. Stay Organized

Last but not least, the very function of tool management software offers one of the best benefits: organization. An organized workplace is a more productive workplace. Having an online database of your equipment and parts will be easier to update/expand and share, and it will better help you reduce redundancies.

Implementing a Tool Tracking System

If you’re looking to decrease production times, identify money-saving strategies, and stay organized, you need a tool data management system. When implementing one into your workplace, be sure to look for one that offers an easy-to-use interface and customization abilities. Additionally, be sure it offers the type of data tracking that you’re looking for.

Learn More About Encore’s Tool Data Management Software

Encore’s proprietary tool data management software was designed for ISO-certified plants that use torque equipment. With our software, you can record specific information about each tool, like the part number and application, as well as repair and calibration data and preventative maintenance dates. Plus, it offers custom reporting generation.

Contact us today to learn more.