The Longevity of DC Motor Controllers

DC motor controllers have been around for a long time, and many industries continue to rely on them, despite their old design. In this article, we highlight what these controllers are, their many types, and why manufacturers still use them.

What Are DC Motor Controllers?

A DC controller can manipulate the torque, speed, or position of a motor powered by DC. Additionally, these controllers can also easily reverse the DC current. Some of the benefits of a DC motor controller include higher starting torque, reversing, and the ability to stop and start quickly.

The Different Types of DC Controllers

Now that you know the function of DC controllers, you also need to know the different types of controllers that are used in manufacturing.

Brushless

A brushless motor controller operates by generating a rotating magnetic field in the motor’s coils. After that, the magnets in the rotor follow and cause rotation.

Brushed

The name “brushed” comes from the brushes that the DC motor utilizes for commutation. The torque and speed are proportional to the applied current and voltage. As a result, it is quite easy to control a brushed DC motor. Brushed DC motors are also more cost-effective than other types.

Shunt

A shunt-wound DC motor, or DC shunt motor, has field windings that are connected to the armature winding in parallel. That means that they get exposed to the identical supply voltage.

Series

Series wound DC motors share quite a few similarities with other brushed DC motors. The rotor and the stator are the two most important components of these motors. The DC power supply is connected to the brushes on the motor, which controls the rotating assembly.

Series controllers are best known for their increased starting torque, but don’t offer as good speed control as some of the other controller types.

Direction Controllers

A direction controller is a simple type of DC motor controller. One type of circuit you can use to control a DC motor is an H-bridge circuit. It consists of four switches that are controlled in pairs. When you close either pair, the pair completes the circuit and powers the motor.

Speed Controllers

A speed DC controller is capable of regulating an electric motor’s direction and speed. It does this because it can manipulate the voltage that you apply to the motor. A speed controller can reverse polarity protection and provide some level of protection against circuit faults.

Armature Controllers

An armature controller influences the motor’s speed because the current fed through the armature is varied. The output shaft’s speed varies with the current variance. This is because the armature’s magnetic field’s strength is proportional to the output shaft’s speed.

AC Versus DC Motor Controllers

One difference between an AC and DC controller is that a DC controller turns direct current into energy while an AC controller turns alternating current into energy. AC motors also have increased efficiency and power output. DC motors, on the other hand, have better output range and speed control. You can get single-phase or three-phase AC motors, but you can only get single-phase DC motors.

Why Industries Use DC Controllers

One reason that DC motor controllers are used in industrial applications is that they’re easier to maintain than AC controllers. DC motor controllers also give you high startup torque and power, and are available at a few different standard voltages.

Find the Right DC Motor Controller With Help From Encore Systems

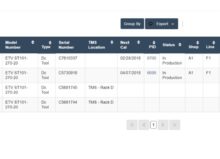

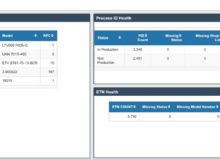

Not sure which type of DC motor controller is best for your business? Contact Encore Systems. We repair and sell a wide array of DC controllers, and are happy to help you select the right one for your application. Click here to view our inventory. If you would like to request a quote, call (937) 249-0712 or fill out our online form today.