When & How to Evaluate Your Existing Tool Management System

Evaluating an existing tool management system is crucial for a company to ensure its continued effectiveness and alignment with evolving operational needs. By conducting a thorough evaluation, the company can identify any inefficiencies, gaps, or limitations in the current system and make informed decisions regarding upgrades, enhancements, or even replacement. This evaluation enables the company to optimize tool tracking, streamline workflows, improve accountability, address compliance requirements, leverage technological advancements, and ultimately enhance efficiency, productivity, and cost savings.

How Often Should You Evaluate Your System

The frequency of evaluating a tool management system depends on various factors such as the size of the tool inventory, the complexity of operations, and the rate of technological advancements. However, it is generally recommended to conduct regular evaluations at least once a year or whenever significant changes occur in the company’s tool usage or processes.

Regular evaluations ensure that the tool management system remains up-to-date, efficient, and aligned with the company’s evolving needs, enabling continuous improvement and optimization.

Common Tool Management System Challenges

Implementing and maintaining a tool management system can pose several common challenges.

These include:

· Ensuring data accuracy and integrity within the system

· Achieving user adoption and providing adequate training to employees

· Addressing scalability and flexibility requirements

· Considering the associated costs.

Overcoming these challenges requires careful planning, effective communication, proper training, ongoing monitoring, and collaboration among various stakeholders.

Let’s look at each of these issues more closely.

Ensuring Data Accuracy and Integrity Within the System

Maintaining data accuracy is crucial in a tool management system, and conducting regular tool sweeps and audits can help ensure the integrity of the data. Tool sweeps involve physically locating and verifying the presence of tools recorded in the system, confirming their condition, and updating any discrepancies. These sweeps help identify missing, misplaced, or unaccounted-for tools, enabling prompt corrective actions. Additionally, regular audits involve a comprehensive review of the tool inventory and associated data, comparing it with the records in the system. This process helps identify inaccuracies, such as duplicate entries or outdated information, and allows for necessary updates.

Achieving User Adoption and Providing Adequate Training to Employees

To promote user adoption, it is crucial to communicate the benefits of the system to employees, emphasizing how it streamlines their work processes, improves efficiency, and reduces errors. Providing comprehensive and hands-on training is essential to ensure that users understand how to effectively navigate the system, perform tasks such as tool check-in/check-out, locate tools, and update records. Training should be tailored to different user roles and supported by clear documentation and ongoing support channels.

Addressing Scalability and Flexibility Requirements

The system should be able to accommodate the company’s changing needs, whether it’s an expanding tool inventory, multiple locations, or evolving operational processes. Scalability ensures that the system can handle an increasing number of tools and users without sacrificing performance. Flexibility allows for customization and adaptation of the system to align with specific workflows and requirements. It should be capable of integrating with other systems and technologies, supporting data exchange and communication.

Considering the Associated Costs

Companies need to evaluate the financial investment required for software licenses, hardware, customization, training, maintenance, and ongoing support. While implementing a tool management system may involve upfront expenses, it is important to consider the long-term cost savings and operational efficiencies it can bring. Comparing different system options, exploring pricing models, and negotiating contracts with vendors can help optimize cost-effectiveness. Companies should also factor in the potential for future scalability and upgrades when considering the costs.

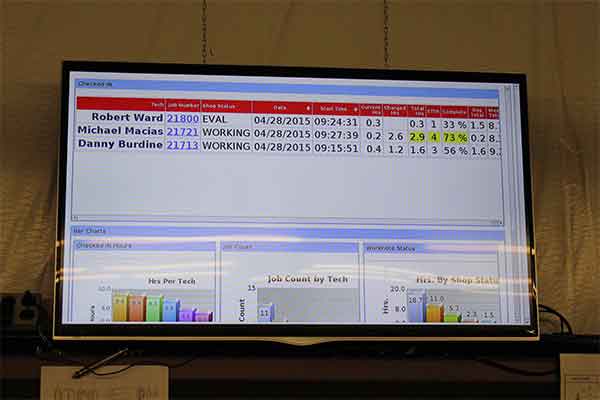

Overall Performance

Consider your current inventory management software’s speed, usability, and scalability. Ask yourself:

- Does it enhance company-wide visibility and reporting?

- Does it simplify your team’s workflow?

- Does it enable you to track team members’ key performance indicators?

- Does it encourage and support simplistic organizational knowledge transfer?

Training Time

Lastly, do your technicians/employees have difficulty using your company’s tool management software? Is the interface too complicated for them to assimilate, understand, and use efficiently? If your system’s backend is slow, clunky, and difficult to use, consider switching to a more modern and intuitive option.

Do You Need to Upgrade Your Tool Management System?

Are you encountering challenges with your existing tool management system? If you’ve been putting off evaluating and possibly replacing your inventory management software, the time to act is now.

Encore Systems offers a fully customizable, web-based QME tool management solution. Our system is designed to help you keep track of your offline and online tools, repair and calibration data, and preventive maintenance schedules, which in turn will help you maintain ISO compliance, reduce unnecessary expenses, and increase data transparency.

Contact us today to learn more about our tool management system.