The Basics of Torque Wrench Calibration

Attempting DIY torque wrench calibration is never a good idea. If you use a torque wrench for your business, you need to have professional calibrations to ensure accuracy. When calibrations aren’t accurate, it could lead to a variety of problems, including the wrench not delivering as much force as it should.

Read on to learn more about the basics of torque wrench calibration.

Why Do You Need Wrench Calibrations?

There are many reasons why you may need a torque wrench calibration. Many of these are related to improper use or storage, but you will need a professional calibration even if you take good care of your wrenches. The reasons that you might need a wrench calibration include:

- Improper Usage: Overloading is one of the most common reasons why people need a professional to calibrate their torque wrench tools. Dropping a wrench during use may also lead to an inaccurate calibration.

- Extreme Climates: Torque wrenches are usually made out of stainless steel, which is resistant to corrosion. However, corrosion can still form (and reduce the wrench’s accuracy) if the wrench is used in temperatures below 32 degrees Fahrenheit or above 120 degrees Fahrenheit.

- Storing the Wrench Improperly: You should store torque wrenches at their lowest setting. Storing a torque wrench at a high setting can weaken its spring, while storing a wrench at zero torque can cause its internal mechanisms to shift.

- Frequent Use: If you use your torque wrenches multiple times every day, you will need to recalibrate it on a regular basis. Even high-end torque wrenches will eventually become inaccurate after months of heavy use.

- High-Precision Projects: If you are about to start a project that requires extreme precision, it’s a good idea to get your torque wrenches professionally calibrated beforehand. Even a difference of 1% could keep you from completing such a job successfully.

How Often You Need to Calibrate a Torque Wrench

The general rule of thumb is that you need to calibrate a torque wrench every month. This guideline doesn’t take into account the fact that some people only use their torque wrenches once or twice a day, while others will use their wrenches a hundred times per day.

When deciding whether your torque wrench needs calibration, you should look at the number of times you’ve used it. ISO 6789 states that a torque wrench should be calibrated every 5,000 uses. Despite this, many professionals calibrate their torque wrench tools every 2,500 to 3,000 uses. It’s important that you keep track of how often you use your wrench so that you know when you have to get it calibrated by a professional.

The Torque Wrench Calibration Process

The calibration process involves several steps carried out by professionals using specially designed sensors. Here’s a step-by-step guide:

- The torque sensor, fixed to a mounting plate, is used. This sensor is shaped like a bolt, allowing the technician to easily put the square drive on it.

- The technician couples the wrench to the torque sensor and ratchets it up and down. The sensor sends the measurement to the technician’s computer.

- The technician compares the amount of torque the wrench is putting out to the desired amount and performs adjustments with a screwdriver.

- The wrench is re-tested. This process continues until the wrench is putting out the desired amount of torque.

Torque Wrench Calibration Standards

Professional calibration services, like Encore Systems USA, follow the ISO 17025 standard, which ensures the highest level of accuracy and reliability in calibration.

Avoid Mistakes by Turning to Industry Professionals

Many people, even some professionals, try to calibrate their torque wrenches themselves, but this can lead to numerous problems. For one, it is very unlikely that you could achieve the same level of accuracy when calibrating a torque wrench yourself instead of taking it to a professional. Even a small error could lead to a big difference in the quality of work on a job that requires you to use a torque wrench many times.

Additionally, you could even damage a torque wrench when attempting to calibrate it yourself. Many people try to calibrate their torque wrenches using a dangerous process that involves putting the wrench on a vice and hanging a weight on the end of it. This process is not only inaccurate, but it can also damage the wrench.

Instead of calibrating the wrench yourself, you should get it professionally calibrated by Encore Systems USA. We have been successfully calibrating wrenches for over a decade. We use the most advanced equipment to ensure that our calibrations are spot-on. Our team follows the ISO 17025 standard, which has enabled us to receive a prestigious accreditation from the American National Standards Institute’s (ANSI) ANAB department. Only the best of the best in the field of tool calibration have this accreditation.

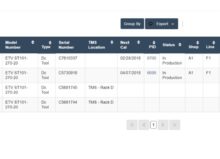

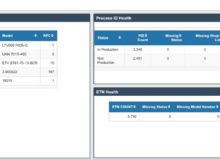

What You Can Expect From Encore Systems

Encore Systems has been at the forefront of tool calibration for many years. When you work with us, you can expect:

- Responsive Customer Service

- Quick Turnaround Times

- Competitive Pricing

- Free Shipping & Evaluation

- Limited Warranties on Parts & Services

We also use the latest technology and methods to ensure that your wrenches are calibrated precisely. Giving our customers the quality and accuracy they deserve is always our top priority.

In addition to calibration services, we can also repair most discontinued or obsolete tools. Call us today to learn more!

We Service a Wide Array of Brands

Encore strives to service tools from all major brands. We service the following brands:

- Bosch

- Uryu

- Aimco

- Cooper

- Stanley

- Atlas Copco

- Sturtevant Richmont

- Desoutter

- Techmotive

- Deprag

- Ingersoll Rand

- FCC Automation Systems

- Estic

- Chicago Pneumatic

If you don’t see the brand you’re looking for on this list, call us today, and we’ll see what we can do for you.

Other Ways You Can Take Care of Your Torque Wrench

As with all tools, it is important to take good care of your torque wrench. A professional calibration will help ensure that it stays accurate for as long as possible. Taking care of your torque wrenches will also extend their shelf life for as long as possible. In addition to taking advantage of professional calibrations, the other ways you can take care of your torque wrench include:

- Lubricating Your Wrenches With Machine Oil

- Inspecting the Screws in the Wrench’s Head to Make Sure That They Are Tight

- Keeping Your Torque Wrenches Dry

- Storing Your Wrenches in an Airtight Case

- Cleaning Your Wrench With a Fresh Cloth Before Storing It

Where to Get a Torque Wrench Calibration

For professional and accurate calibration, consider Encore Systems USA. We specialize in electric/DC torque tool calibrations and have been successfully calibrating wrenches for over a decade. Our team follows the ISO 17025 standard, which has enabled us to receive a prestigious accreditation from the American National Standards Institute’s (ANSI) ANAB department.

If you have any questions about our services or about torque wrench calibration in general, you can contact us online or call (937) 249-0712. We’re always here for you.