Exploring the Range of DC Torque Tools Offered by Encore Systems

DC torque tools are crucial in assembly applications because of their precision, consistency, and efficiency. The repeatability of these tools minimizes the risks of under-tightening or over-tightening fasteners, reducing the likelihood of product failures or quality issues. They also enhance productivity by speeding up the assembly process and reducing physical strain on technicians.

If you’re looking for high-quality DC assembly tools, Encore Systems is here to help. We refurbish and sell many types of assembly tools, torque controllers, cables, and essential components. Keep reading to learn more about the tools we offer.

Torque Tools We Offer

Angle Nutrunners

- Advantages: Enhances accessibility in tight spaces and provides better ergonomics to reduce operator fatigue.

- Disadvantages: May be slightly less accurate compared to inline models due to the angle drive.

- Common Uses: Angle nutrunners are ideal for assembly applications in confined spaces or complex assemblies in the aerospace, automotive, and construction industries.

Pistol Grip Nutrunners

- Advantages: Ergonomic design allows for comfortable grip and ease of use in various positions.

- Disadvantages: Not the best option for space-constrained areas.

- Common Uses: Pistol grip nutrunners are best used for repetitive or lengthy fastening applications, as their ergonomic design helps reduce wrist strain.

Straight Nutrunners

- Advantages: Great for reaching narrow or deep recesses, offers precise torque control, and can be found in various torque ranges, making them suitable for a wide range of applications, from delicate electronic assemblies to more heavy-duty industrial applications.

- Disadvantages: They are not as versatile in tight or awkward spaces where angled or more compact tools would be more effective, and in some scenarios, operators might have to overreach to use the tool effectively.

- Common Uses: Straight nutrunners are well-suited for accessible fastening positions, like engine or chassis assembly.

Inline Electric Screwdrivers

- Advantages: Offers precise torque control and alignment and is ideal for assembly operations that require straight-line configurations.

- Disadvantages: Might be less ergonomic for operations requiring numerous or complex angles.

- Common Uses: Inline screwdrivers are particularly suited for applications where direct, inline access to the fastener is available.

Transducerized Screwdrivers

- Advantages: Because these screwdrivers feature built-in transducers, they provide real-time feedback and data logging, allowing immediate quality control and traceability in assembly processes. Transducerized screwdrivers are also often designed to be ergonomic and reduce operator strain.

- Disadvantages: Transducerized screwdrivers are generally more expensive than simpler, non-transducerized tools, and may require additional training.

- Common Uses: Transducerized screwdrivers are primarily used in applications like medical device assembly, where accuracy, quality control, and traceability are critical.

DC Torque Wrenches

- Advantages: Provides highly accurate torque control, reducing the variability found in manual wrenches. Some DC torque wrenches can record data and provide feedback to help with quality control and process optimization.

- Disadvantages: Technicians may need extra training to use DC torque wrenches effectively, especially if they have advanced features and data capabilities.

- Common Uses: DC torque wrenches are ideal for many high-precision assembly applications within the automotive, aerospace, construction, railroad, military/defense, electronics, and energy industries.

Impact Wrenches

- Advantages: This type of wrench delivers a high level of torque, allows for quick and efficient loosening of over-torqued or rusted fasteners, and significantly speeds up the fastening process. They are also available in various sizes and powers to suit different applications, from light automotive repair to heavy-duty construction work.

- Disadvantages: Impact wrenches do not offer the same level of precision as a standard DC torque wrench. Impact wrenches can also be quite loud, produce significant vibration, and are heavy and bulky, making them less suitable for use in tight spaces or for extended periods.

- Common Uses: Impact wrenches are great for applications that require loosening or tightening heavy-duty fasteners or for applications requiring high torque.

Brands We Carry

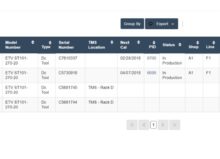

Encore Systems carries refurbished DC torque tools, including discontinued or obsolete models, from brands like Atlas Copco, Stanley, and Cooper/Cleco.

Atlas Copco assembly tools are known for their precision, advanced ergonomics, reliability, and energy efficiency; Stanley DC tools generally offer a high power-to-weight ratio, feature user-friendly interfaces, and are made to withstand tough industrial conditions; and Cooper/Cleco tools are known for being compact and lightweight, easy to integrate into existing assembly lines, and durable in repetitive industrial applications.

Please visit our website to view a list of line cards, or contact our experts today if you need help finding the best replacement torque tool.

Additional Services

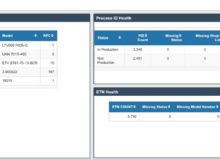

Encore Systems offers reliable repair and ISO 17025 torque calibration services for DC assembly tools. Whether you need us to fix a damaged nutrunner or maintain refurbished equipment you bought from us, we’re here to help.

Get Reliable Assembly Solutions From Encore Systems

Find what you need at Encore Systems. Visit us online to browse our wide range of DC torque tools, or contact us today to learn more about our services or to request a product quote.