Diagnosing Electric & Pneumatic Torque Tool Issues

Electric and pneumatic torque tools are essential for any assembly operation. A tool that isn’t outputting the correct amount of torque is a security risk. That’s why it’s important to resolve torque tool issues as quickly as possible.

In this article, we’ll cover some of the most common issues we see with both electric and pneumatic torque tools and how to resolve them.

Causes of Common Issues With Electric Torque Tools

Clutch Failure (Electric Screwdrivers)

An electric screwdriver’s clutch regulates the torque amount that is applied to bolts or other fasteners. A functioning clutch will prevent overdrilling as soon as the desired torque is reached. An unstable torque, incorrectly installed bit, low-quality bit, or broken output shaft can cause the clutch to fail.

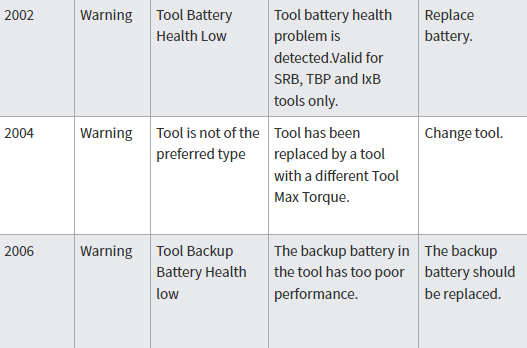

Doesn’t Display Error Codes (Electric Nutrunners)

Next, most electric nutrunners display error codes that tell users exactly what kind of operational failure the nutrunner is experiencing. You can find descriptions of error codes in manuals. These codes vary according to the manufacturer and nutrunner model type. You will often see displayed error codes when an electric nutrunner is overheating or the tool has exceeded the torque rate.

Odd Noises or Odors (Electric Torque Wrenches)

Lastly, another common issue with electric torque tools is odd noises and/or odors. Low-quality or loose bearings in the gearbox of an electronic torque wrench will produce vibrational sounds. Burning smells emitted by electronic torque wrenches are typically the result of a motor going bad. Always turn off the wrench immediately if it makes unusual sounds or gives off a scorching smell.

Common Issues With Pneumatic Torque Tools & Their Causes

Slowing or Stalling Under Certain Loads

Pneumatic torque tools require regular calibration and maintenance. Failing to maintain your torque tool can cause slowing or stalling. Regular lubrication of pneumatic torque tools is critical to optimizing how well the tool performs under heavier loads. You should lubricate frequently used pneumatic torque tools at least once a day.

Additionally, torque tools made with low-quality components often fail to provide the necessary power, although manufacturers may claim otherwise.

Displaying Incorrect Pressure

Worn gaskets or seals, excess moisture inside the tool, and a damaged regulator can cause insufficient pressure issues. Usually, too much moisture in a pneumatic torque tool actually causes rapid damage to gaskets and seals. Lubricating tools with manufactured-approved oil or grease should decrease friction and inhibit water contamination.

Do You Need Repairs or a Replacement?

When it comes to electric and pneumatic torque tool issues, it can be challenging to understand whether a repair or replacement is the most cost-effective choice. The best way to know whether a repair or replacement is the right choice is by consulting with an expert at a torque wrench service center.

Service centers can usually fix most torque tool problems, but only if it’s been regularly calibrated and maintained. If the damage is severe and you have not been properly maintaining your tool, you may need to replace it entirely. We recommend replacing your damaged tool with a new tool if the cost of repair is at least half the cost of a replacement. In most cases, this is a more cost-effective decision and results in a better return on investment rate.

Are You Experiencing Issues With Your Electric or Pneumatic Torque Tool? Contact Encore Today!

Not sure how to resolve your electric and pneumatic torque tool issues? Get in touch with Encore Systems today! With over 20 years of experience repairing and calibrating nutrunners, electric torque wrenches, and more, Encore is considered one of the leading, most reputable companies in the industry.

We service brands like Stanley, Deprag, Atlas Copco, and more, and even have a convenient tool exchange program to help you prevent downtime in your facility.

If you need help diagnosing your torque tool issues, please reach out to us today for a free evaluation.