4 Methods of Verifying Torque

Torque verification is critical in preventing under-tightening and over-tightening, both of which have severe consequences and can result in component failure and safety risks.

Although torque tools are manufactured for reliability, they can and will drift over time in service. Sometimes this drift takes time to appear, but it can also happen instantly if a tool is dropped or takes an impact. If it occurs soon after the tool is recalibrated, there’s a risk of applying the wrong torque to thousands of assemblies before the problem is discovered.

So…how do you verify that you’re applying the correct torque?

1. Use Torque Sensors

Torque sensors use strain gauges to measure torque. As torque is applied, the sensor twists slightly between the top and bottom, deforming the strain gauge and altering its electrical resistance. By incorporating the sensor into a Wheatstone Bridge electrical circuit, it’s possible to measure the amount of distortion applied and convert it to a torque measurement.

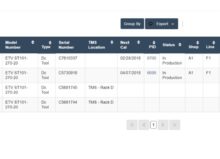

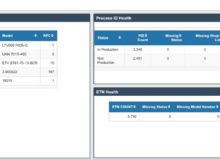

This type of torque sensor, technically a reaction sensor, can be used on an audit basis in production. Several fasteners are tightened, and the torque readings from the sensor are compared with the tool’s settings. If they disagree, the tool should be taken out of service and sent for calibration.

2. Measure Dynamic Torque

Dynamic torque is the torque a tool generates as it tightens a fastener, and measuring it requires a rotary torque sensor that captures the entire torque-angle curve. These sensors often use slip rings to transfer displacement information that shows torque-induced distortion.

Modern torque tools now have this kind of sensor built in to enable precision tightening. The usual method of verifying the dynamic torque a tool is producing is to use a joint simulator in a laboratory. A trained technician follows a defined procedure in which the torque tool undergoes multiple fastening cycles. The joint simulator captures torque, angle, and speed information, which is compared against the tool settings. If results are outside the tool’s stated accuracy, the tool should be recalibrated.

3. First Movement Tests

This verification method determines the torque needed to increase the tightness of the fastener. It’s a static method that involves monitoring the position of the screw, bolt head, or nut as torque is increased.

Movement, as indicated by a torque stripe (see below), shows the torque at which the fastener was tightened. This can be compared to the torque settings used on the tool to determine if it is operating within limits or needs calibration.

While relatively easy to perform, first movement tests have limitations. They should be carried out immediately after the fastener is torqued to avoid cold welding/adhesion. Additionally, by raising torque on the fastener, first movement tests increase extension and take it closer to its yield point.

4. Implementing Torque Stripes

While torque stripes don’t verify that a specific torque was applied to a fastener, they do indicate whether it has moved during service.

A torque stripe is a line of paint or other adhesive material (often similar to a silicone bead used for caulking) applied over the fastener and onto the fixed surface. Any movement of the screw, nut, or bolt head will show up as misalignment in the stripe. It’s a simple, effective way to monitor torque-tightened joints.

Prevent Drift With Encore Systems

Torque verification is important for monitoring equipment performance and protecting products against assembly faults. However, it should never be a substitute for regular calibration.

When conducted to a defined schedule, such as operating cycles or hours, adjustments can be made before risky assembly scenarios occur. Routine calibration also generates historical data that helps monitor usage trends and determine when a rebuild or replacement will be needed for that specific tool.

Encore Systems maintains an ISO 17025-accredited laboratory for performing DC torque tool calibration, along with comprehensive inspections and repairs.

Visit our website to learn more about our capabilities, or contact us today to schedule a free evaluation.