Costly Tool Management Mistakes

Tool management involves identifying, tracking, and, most importantly, maintaining the devices and equipment used throughout production. The task requires accurate reporting, precise data maintenance, and a good eye for detail. When it isn’t done, tools break in service and can perform incorrectly as a result of damage and calibration drift.

Unfortunately, amid the pressure of hitting production and cost targets, tool management often gets pushed down the “to-do” list and is usually seen as an “essential, but not urgent” task.” task.

Most manufacturers already have some program in place, often based on Excel spreadsheets and using incomplete data, and they typically don’t work well.

This article looks at four common and costly tool management mistakes and offers some advice for running an effective program.

#1 Failing to Label Offline Equipment

When tools are sent out for repair, maintenance, or calibration, production needs to know. Without an effective means of identifying what’s not available, there’s a risk of significant disruption. While it may be possible to purchase replacement tools, this takes time, and work will be halted until the new tools are available.

If the tool or tools are only used infrequently, there may be a suspicion that they’ve been misplaced, in which case a major search exercise will be launched, pulling people away from other activities and disrupting work in other departments.

Given pressure to hit output targets, managers may decide to continue production, but segregate product until tools are available to complete missed operations. Alternatively, the product may go through with fasteners incorrectly tightened or other assembly defects.

#2 Taking a Reactive Approach to Maintenance

In most plants, there is a constant pressure to keep production running, which influences a reactive versus proactive approach to tool maintenance. Yes, maintenance means downtime, and while taking a reactive approach may seem like it minimizes disruption, it is very costly in the long run.

The primary issue is that faulty tools lead to quality defects. They can even result in accidents and injuries. This is why a proactive approach to tool management is always preferred.

In a proactive tool management program, tools are sent for maintenance, repair, and calibration at scheduled intervals. This ensures they are inspected, that wear and faults are identified and addressed, and that calibration is performed before any problems arise.

A proactive approach requires an efficient system of identification and tracking, as well as the availability of replacements to prevent production disruptions. The costs of providing this are almost certainly lower than customer returns, warranty claims, and OSHA investigations.

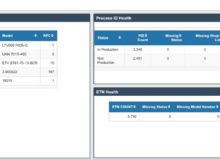

#3 Not Tracking Usage Trends

Tools seldom wear when not in use. Admittedly, some components, such as seals, can deteriorate while a tool is on a bench or storage rack; however, most deterioration occurs when the tool is in use. Maintenance periods should be set accordingly.

Closely spaced maintenance intervals on a tool with low usage are usually unnecessary. Conversely, following an OEM-recommended annual interval on a tool used 24 hours a day, seven days a week, may be too little.

The answer is to track the usage of each tool in the management program. With this information, it’s possible to determine optimal maintenance intervals. It also becomes easier to track its lifecycle and determine the most cost-effective replacement timing.

#4 Failing to Establish Reorder Points

Planned maintenance can run into problems when key wear components aren’t available. This is addressed by determining optimal reorder points based on historical usage records, purchasing history, and knowledge of supplier lead times and minimum order quantities.

For some tools, it may be more cost-effective to keep complete tools as backups, rather than holding spares. However, the same issue applies: depending on lead time, it may be necessary to have multiple units available to minimize the risk of running out.

How Encore Systems Can Help You Avoid These Mistakes

With the intense focus placed on output targets and costs, tool management is sometimes left on the back burner. Everyone knows it’s needed, but there’s never time to do it well.

The solution is to entrust the work to an organization with the time, resources, and expertise to give it the attention it needs.

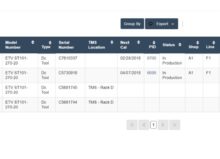

Encore Systems offers an all-encompassing management program for assembly tools. How it works is simple: we customize software based on your plant’s needs and provide an on-site team of experienced technicians to handle calibrations and repairs as they’re needed.

Core features of our program include:

- Repair work

- Data logging

- Comprehensive documentation

- Calibration to ISO 17025

- Preventive maintenance schedule management

- Reporting as needed

Learn More Today

An effective tool management program ensures essential equipment is ready to use when needed and will deliver the expected results. There’s more to it than creating a spreadsheet and attempting to stay on top of the work required. To avoid mistakes that undermine the whole program, the best approach is to work with a specialized organization like Encore Systems.

Contact us today to learn more about our assembly tool management program and other capabilities.