How You Can Extend Tool Life Through Reconditioning

A DC assembly tool falls on the floor, and the case cracks. What should you do—repair or replace it? If the repair will cost more than 50% of a new tool, many businesses opt for a replacement. While that may make sense, there is a third option that’s often overlooked: reconditioning.

Reconditioning helps lower your spend on DC assembly tools, and if you’re under pressure on budget, it’s a great way of making your dollars go further.

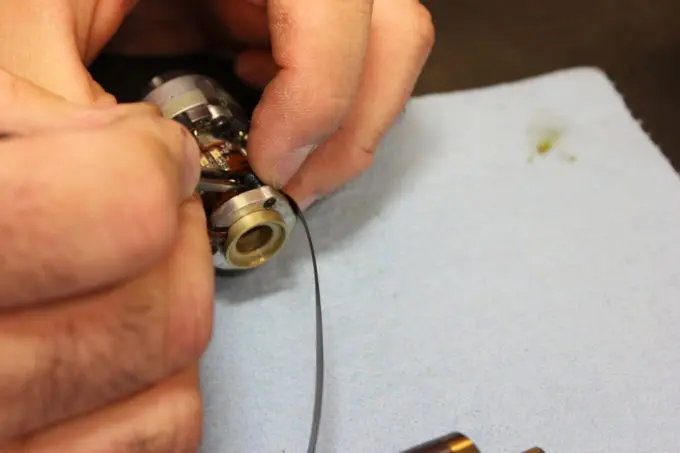

DC torque tools are complex and expensive, yet they’re also essential for productivity and quality. Damage is common in busy plants, and with intense use, they will quickly start to show wear, including bent shafts, frayed cables, and cracked housings.

When any of these occur, the usual step is to send the tool out for repair, which solves the immediate problem, but then you end up with an old tool with one or two new parts.

When Is Repairing Not Enough?

If the tool is still young when damage occurs, a repair is likely to be sufficient. However, repairing often doesn’t make sense on older tools, though, because it doesn’t extend their life.

In “Should You Repair or Replace Your Assembly Tools?,” we looked at the 50% rule and the 50-70 rule, both of which are useful guides for when to repair and when to replace.

For example, on a newer, though out-of-warranty, DC torque tool, it’s worth repairing if the cost is less than 50% of the cost of a new replacement. However, if the tool is more than halfway through its expected life, the 50-70 rule shifts to consider the remaining life.

Reconditioning As an Alternative to a Replacement

The alternative to replacing an older broken tool is to get it reconditioned, although it doesn’t have to be broken to be reconditioned.

Reconditioning is different from repairing. When a tool fails or is suffering from severe wear, a repair entails stripping it down, replacing the damaged parts, and putting it back together. Comparatively, reconditioning involves replacing all the parts that wear out with new parts. Reconditioning essentially gives you a new assembly tool, while repairing gives you a tool that works until the next part fails.

The primary benefits of tool reconditioning are speed, cost, and the opportunity to upgrade.

Speed

Getting the exact tool you need from the OEM or their distributor can take time. You need to check specs, determine pricing, and possibly go through several levels of internal approval before even placing the order. And once that’s done, the product might ship from Europe or even China.

Reconditioning can be faster, especially when you work with a U.S.-based partner like Encore Systems.

Cost

Reconditioning is less expensive than buying new because there are always non-wear components that get reused. Not only does that let your tool replacement budget go further, it also means you can do other projects you didn’t think there would be money for!

Upgrade Opportunities

When reconditioning an assembly tool, the technician may suggest upgrades if the specific parts needed are no longer available or if they’ve identified that a particular upgrade will improve performance and life.

Determining If Your Assembly Tool Is Qualified for Reconditioning

Three factors to consider are:

- Age/use

- Condition

- Spare part availability

Newer tools can be reconditioned, but the limitation is that the impact on their overall service life is small. To provide a specific example, if a tool is only a year old, reconditioning might add another year of life. If it’s four years old, reconditioning might add another four or five years of life, making it an attractive alternative to buying new.

If the tool is in good condition, with just the expected level of wear in service life components, reconditioning will often make good sense. But if it has been run over by a forklift, there may be very little of it that can be reused.

Reconditioning also assumes spare parts, or upgraded versions of them, are available. This is where it’s beneficial to work with companies specializing in DC torque tool repair and reconditioning, because they have access to this information.

See If Your Part Can Be Reconditioned

Encore Systems supports manufacturing operations through our in-house assembly tool repair, calibration, and reconditioning capabilities. We understand the importance of time and money, and have structured our operations to provide the best quality service at the lowest possible cost and in the least time possible.

It’s hard to know if a tool can be reconditioned without a comprehensive evaluation. Request your free evaluation here.